|

2440P-04V32氢气软管 - 派克 Parker

派克2440P-04V32氢气软管符合高压加氢应用的高要求。. 该软管稳定性高、设计坚固,寿命周期非常长,适合用于875 bar的加氢站。

高压软管总成

产品介绍:

随着氢气被视作清洁能源而迅速异军突起,因此而被广泛关注。派克 Polyflex 专门针对加氢站/

加氢机推出的2440P-04V32HT-P 软管,是市场上第一款适用于70 MPa 加氢系统的软管产品,其

性能卓越,优势显著,进而备受广大用户的喜欢和青睐。

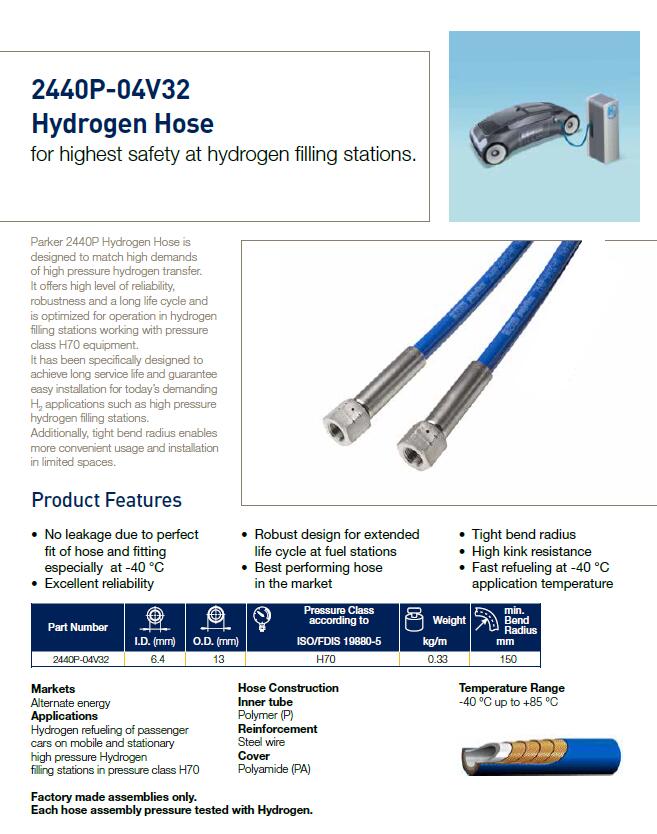

2440P-04V32 Hydrogen Hose

技术参数:

- 尺寸:1/4"(DN6)

- 工作压力:1035bar

- 安全系数:4:1

特点& 优势:

- 市场第一款适用于70 MPa 氢能源系统的高压氢气软管

- 工作压力高达1035 bar, 符合ISO19880-5 要求

- 低温环境(-40℃ ) 也能实现无泄漏连接并快速加氢

- 耐磨性优异,耐臭氧能力好,抗紫外线,适合户外安装

- 弯曲半径小且抗扭结,持久耐用,性能可靠

- 重量轻,抗振动

- 匹配Polyflex 特定形式不锈钢软管接头扣压

- 软管总成由德国Polyflex 工厂扣压,无泄漏

产品型号/ 选型: 2440P-04V32-HT-P

加氢站不仅需要高品质的仪器仪表产品,还有赖于安全可靠的流体连接件。例如,在为汽车加注燃料时,加氢机需通过高压软管将氢燃料输入车载高压储氢瓶。派克旗下的 2440P-04V32HT-P 软管正是面向 70MPa 加氢站的高压氢气加注而开发的产品。

该软管凭借其各方面的出色性能成为加氢站工作人员的理想选择:

- 弯曲半径小,方便用户在有限的空间使用和安装;在加氢机和汽车之间建立安全灵活的高压连接,工作压力高达 875bar

- 符合 ISO-19880-5 要求,可在 -40℃的低温环境下实现快速加氢

- 该软管配上护套后耐磨性更高、耐臭氧性更好、抗紫外线能力更强,便于安装在户外

这些特性不但有效改善氢气渗透,还能显著提升氢气系统运行安全,消除最终用户的诸多担忧。

Parker Introduces Polyflex 2440P-04V32 HT-P Hydrogen Hose for Fast Compressed Hydrogen Refueling of Fuel Cell Electric Cars

Flexible high-performance solution based on new ISO 19880-5 standard combines safety and an enhanced life cycle

Lampertheim, Germany, 1. April 2019 – The Polyflex Division of Parker Hannifin Corporation, the global leader in motion and control technologies, has announced the launch of its new Polyflex 2240P-04V32 HT-P Hydrogen hose developed specifically for high pressure hydrogen refueling of fuel cell electric cars. The ISO 19880-5 complianthoses allow very fast refueling at temperatures as low as -40°C.

Polyflex Hydrogen Hose has a nominal internal diameter of 6.4 mm (1/4 inch) and a minimum bend radius of 150mm (5.90"). An industry-leading 875 bar working pressure allows dispenser manufacturers to overcome the constraints of slow and low-pressure hydrogen refueling. The hoses provide a safe and flexible high-pressure connection between dispenser and passenger car. Pressure tested to H70, mainly in accordance with ISO DIS 19880-5 makes 2440P-04V32 HT-P hydrogen hose an excellent choice for operators facing variable and unpredictable operating conditions at fuel stations.

“Today’s dispenser manufacturer engineers want robust solutions that provide 100% safety, have an easy-to-use design, and an extended life cycle,” said Alexander Hertje, Market Development Manager of Parker’s Polyflex Division. “Parker is continually advancing its hose product offering to meet the expanding challenges of tomorrow. The new Hydrogen dispenser hose has enhanced performance features at longer life cycles,” Hertje added. “Its tight bend radius allows space saving installations, and its high abrasion resistance as well as high ozone and UV resistant cover support deployment outdoors and reduce the risk of abrasion-related problems as well as cover cracks.”

Parker’s newest hydrogen hose features a high-performance thermoplastic inner core tube protected by four layers of high-tensile wire reinforcement. With a wide operating temperature range of -40°F to +185°F (-40°C to +85°C), high cleanliness, and an extremely low permeation rate, 2440P-04V32 HT-P Hydrogen hose is highly suitable for H70 pressure class dispenser applications.

|

![]()