|

Parker 流量控制器

Parker Flow Controllers

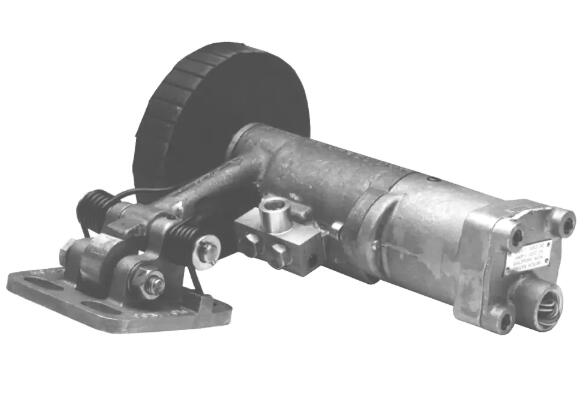

顺序控制阀 - 派克的 Conflow 200系列 Sequence Control Valve - Code 200

派克的Conflow 200系列是一种顺序控制阀,它通过检测传送带在尘埃抑制应用中的运动来激活电气设备。这是一种不需要自备电源的机械阀。

Parker Conflow's Code 200 is a sequence control valve which switches on electrical equipment by detecting the movement of a conveyor belt in dust suppression applications.

派克的Conflow 200系列是一种顺序控制阀,它通过检测传送带在尘埃抑制应用中的运动来激活电气设备。这是一种不需要自备电源的机械阀。

Parker Conflow's Code 200 is a sequence control valve which activates electrical equipment by detecting the movement of a conveyor belt in dust suppression applications. It is a mechanical valve that does not require its own power supply.

派克的Conflow 200系列通过一个驱动轮进行操作,该驱动轮与移动输送带进行摩擦接触,不需要额外的电源。旋转轮产生液压动力去关闭安装在内置模块上的微动开关,这表明控制室是否传输带是文具或移动的。

Code 200 operates via a drive wheel, which is in frictional contact with the moving conveyor belt and requires no additional power supply. The rotating wheel generates hydraulic pressure to close a microswitch built in to the unit, which indicates to a control room whether the belt is stationery or moving.

市场Markets:

- Quarrying

- Mining

- 采石厂

- 采矿业

特点/优势Features/Benefits:

- Enables sequence control of associated conveyer belts and auxiliary equipment.

- No power required for unit.

- Still very effective at low belt speeds, down to 0.5 m/sec .

- Can be adjusted to varying belt speeds.

- Compact tried and tested design from CODE 100.

- Can be positioned underneath belt to prevent damage.

- Low maintenance.

- All spare parts available to replace.

- 对相关传送带和辅助设备进行顺序控制。

- 机组无需电源。

- 在低速皮带运转下仍然非常有效,即使速度下降到0.5米/秒。

- 可根据不同的皮带速度进行调整。

- Conflow 100系列中经过严格测试和测试的设计。

- 可放置在皮带下方不被损坏。

- 低维护。

- 各备件可替换。

应用Applications:

- Belt Conveyors

- 带式输送机

Technical Specifications

| Materials of Construction: |

Brass |

| Application: |

Dust Supression |

| Industry: |

Mining |

| Minimum Operating Speed: |

100 ft/min |

| Maximum Operating Speed: |

500 ft/min |

| Weight: |

9.5 kg |

Sequence Control Valve - Code 200 型号

CODE-200-V1

|

![]()